09

2025

-

01

How much do you know about cleanroom gloves?

Author:

In today's rapidly developing technological era, many industries have increasingly high requirements for the cleanliness of production environments. In clean rooms, gloves play a crucial role. They are like the "hands" that protect delicate craftsmanship, safeguarding countless high-tech industries.

What are clean room gloves?

Clean room gloves, as the name suggests, are gloves used in clean room environments.Clean room gloves have very high cleanliness.,其本身的They have very low particle release.Additionally, they can prevent contaminants released from human hands from transferring to products.

In industries such as electronics, semiconductors, optics, aerospace, precision manufacturing, and food, tiny dust and bacteria can severely impact product quality.Clean room gloves are indispensable equipment.They can effectively prevent contaminants from affecting products, ensuring product performance and reliability.

In industries such as biology, pharmaceuticals, and healthcare, they are even more critical to the accuracy of experiments and patient safety.Clean room gloves can reduce the spread of particles and microorganisms,ensuring the cleanliness of production and treatment processes.

Therefore, clean room gloves must besubjected to strict cleaning processes,to ensure they meet the cleanliness level requirements of clean rooms. In sterile environments, clean room gloves must also besterilized,to ensure that each pair of gloves meets the requirements of being dust-free and sterile.

The cleanliness level standards of clean rooms.

Different cleanliness levels correspond to different particle concentrations; the lower the particle concentration, the higher the cleanliness level. It is the core indicator for evaluating environmental cleanliness.

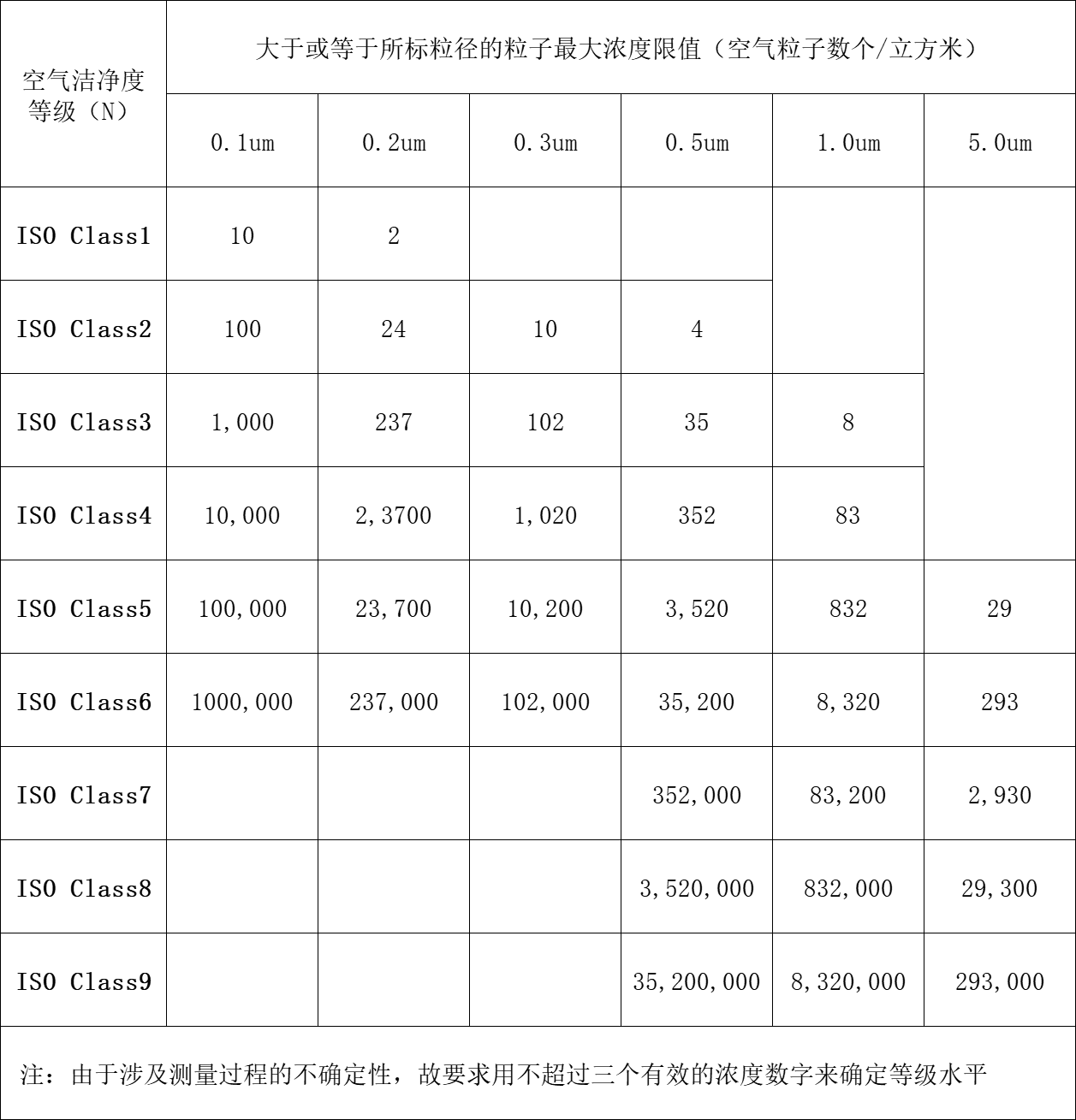

ISO14644-1 (International Standard):

The smaller the number in these level names, the higher the cleanliness. ISO1 has the highest cleanliness, while ISO9 has the lowest.

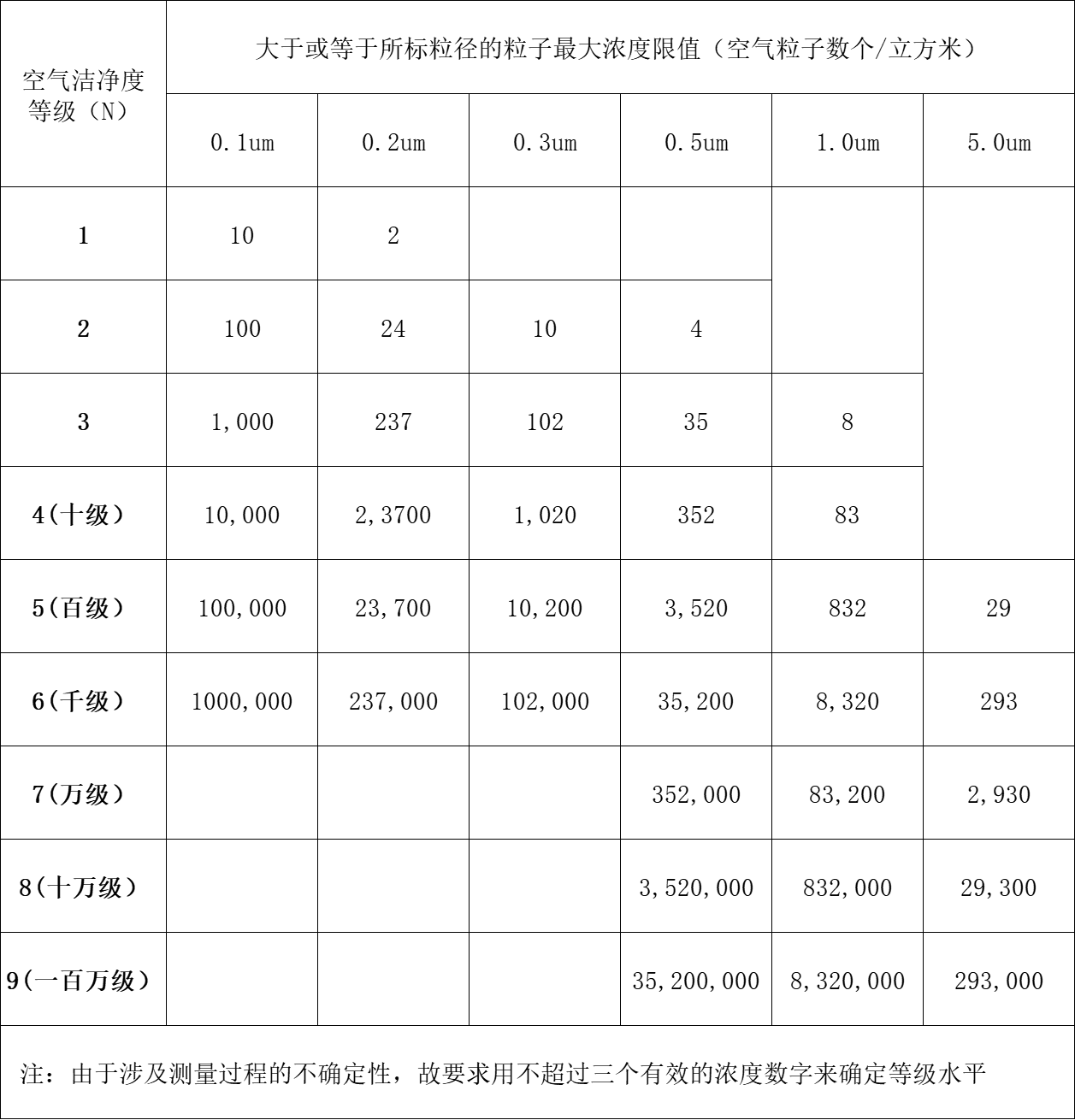

GB/T 25915.1-2021 (National Standard):

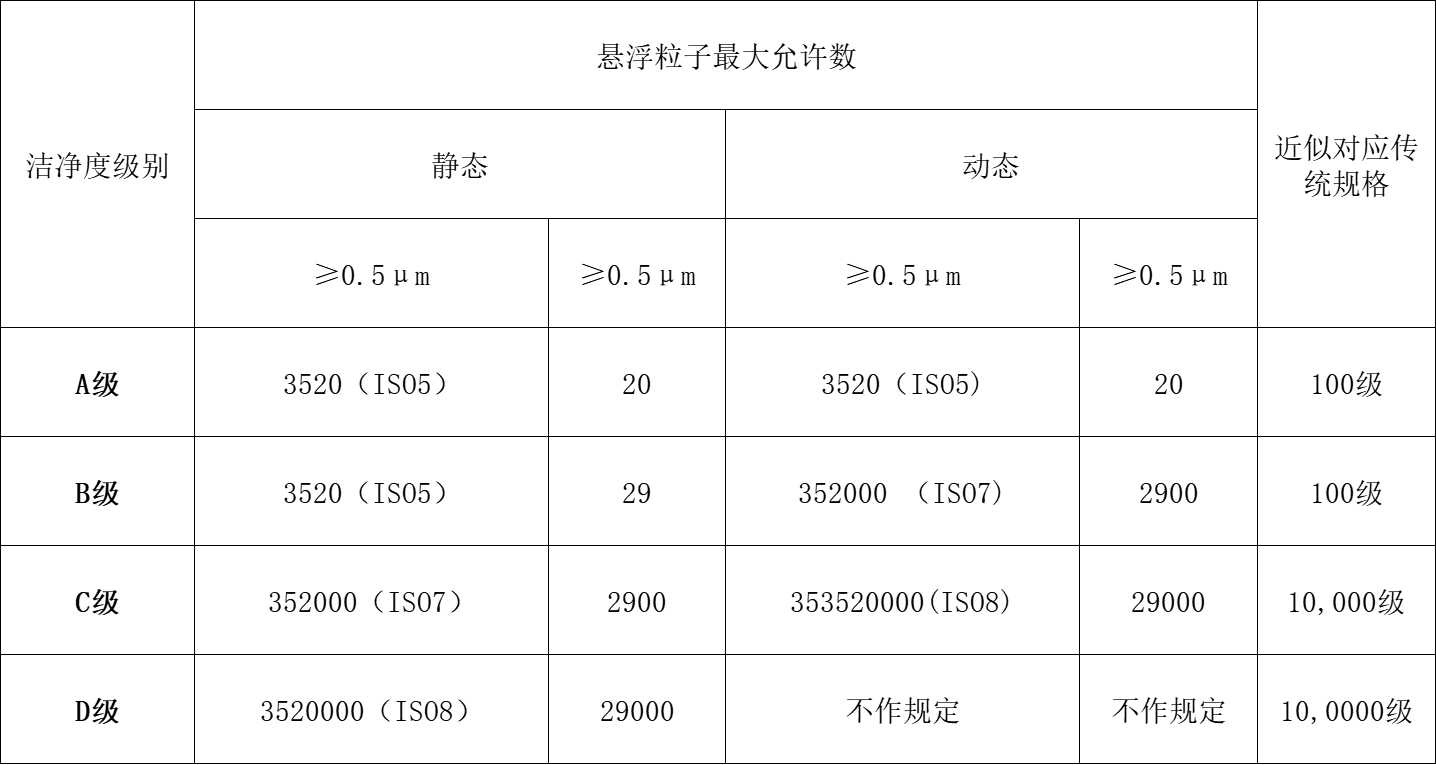

GMP clean room levels (International Standard):

(Static: refers to the state of the clean room or clean area when it is built and the equipment is in place, but there is no personnel activity, no equipment operation, and no production operations.)

(Dynamic: the clean room or clean area facilities operate as agreed, with a specified number of personnel operating and equipment running according to the agreed method during production operations.)

The correspondence between different cleanliness standards is roughly as follows:

ISO3 corresponds to Class 1.

ISO4 corresponds to Class 10.

ISO5 corresponds to Class 100.

ISO6 corresponds to Class 1000.

ISO7 corresponds to Class 10000.

ISO8 corresponds to Class 100000.

Class A corresponds to ISO4.8 or higher.

Class B corresponds to ISO5 or higher.

Class C corresponds to ISO7 or higher.

Class D corresponds to ISO8 or higher.

Depending on the application needs of different industries, gloves of different cleanliness levels can be used:

1. Ordinary gloves: suitable for general industries, households, etc., with no high cleanliness requirements.

2. Medical examination gloves: suitable for medical protection, epidemic prevention, dental clinics, and other industries with certain cleanliness requirements.

3. Sterile gloves: suitable for biology, pharmaceuticals, and other situations with high cleanliness requirements that need to be clean and sterile.

4. 10-1000 level clean room gloves: suitable for electronics, semiconductors, precision instruments, and other fields with higher cleanliness requirements.

Select gloves based on performance indicators.

According to the different levels of clean rooms and product requirements, some or all of the following tests may be conducted:

1. FTIR testing (Fourier Transform Infrared Spectroscopy): detects whether gloves contain silicone oil, amino compounds, plasticizers, etc., and their content. Although FTIR testing can only provide semi-quantitative data, it can serve as one of the preliminary screening tools.

2. LPC testing (Liquid Particle Counting): assesses the particle content on the glove surface, which is one of the important indicators for cleanliness evaluation.

3. NVR testing (Non-Volatile Residue Testing): detects the content of non-volatile residues on the surface of clean gloves, which is also one of the main indicators for cleanliness evaluation.

4. IC testing (Ion Testing): detects the level of extractable ions on the glove surface, which is also an important indicator for evaluating cleanliness.

5. GC testing (Gas Chromatography for Volatile Organic Compounds): a method used to analyze the types and content of organic pollutants on gloves.

6. ESD testing (Electrostatic Discharge Testing): examines the anti-static performance of gloves, especially suitable for situations that require prevention of static interference.

Select gloves based on material.

Currently, clean room gloves mainly come in the following three types:

1. Latex gloves:

Latex gloves are mainly made from the natural latex sap of rubber trees combined with stabilizers through specific processes,offering good elasticity and stretchability.They fit the contours of the hand well, providing a good grip. Their cost is relatively low, but they have poor ESD performance, higher extractable ion content, and contain proteins that can cause allergies and dermatitis.

2. Nitrile gloves:

Nitrile gloves are primarily a synthetic polymer made from acrylonitrile, butadiene, and carboxylic acid. They do not cause allergies or dermatitis because they are protein-free.They are also resistant to chemical solvent corrosion, and their mechanical properties, ESD performance, NVR levels, extractable ion content, and LPC levels are allsuperior to latex gloves and PVC gloves.However, they have poorer elasticity and a weaker fit compared to latex gloves.3. Vinyl Gloves (Vinyl/PVC):

PVC gloves are mainly made from the synthetic material PVC, along with certain catalysts and other chemical components, processed through specific procedures,

which have good chemical stability and are suitable for handling various chemicals.They are lower in cost, but the residual catalyst substances can cause allergies and dermatitis, and they have poor elasticity, are prone to tearing, are not corrosion-resistant, and generate dust, with high extractable ion content and NVR levels,making them suitable for use in lower-grade cleanroom environments.Powder-free gloves/Chlorination process

refers to the addition of talcum powder, corn starch, etc., to the inner layer of some gloves for ease of donning and production processes. Powdered gloves can introduce unnecessary dust interference during experiments,

so they should be avoided as much as possible.Powder-free gloves can be treated using the chlorination process,

which effectively removes powder.Whether natural rubber or synthetic rubber, both can use the chlorination process. By treating the protein on the glove surface with chlorine gas, the chlorine will react with the protein, denaturing the soluble protein and making it lose its water solubility,resulting in gloves that are increasingly smooth.This makes them easier to wear.Typically, the chlorination process is divided into primary and secondary chlorination. Gloves that have undergone secondary chlorination will be cleaner,and the amount of powder contained will be significantly reduced.To ensure that no solutions remain on the gloves, there will be certain follow-up treatments after chlorination. Ultimately, after the chlorination process, the friction on the inner surface of the gloves will be greatly reduced, making them easier and smoother to wear, achieving the final goal.

Texture/Matte surfaceTo increase the stability of hand operations after wearing gloves, some gloves will have a textured/matte surface design added on the outside,which increases the friction after wearing, making them more slip-resistant, better for handling precision components or instruments, and eliminating worries about knocking over reagent bottles!

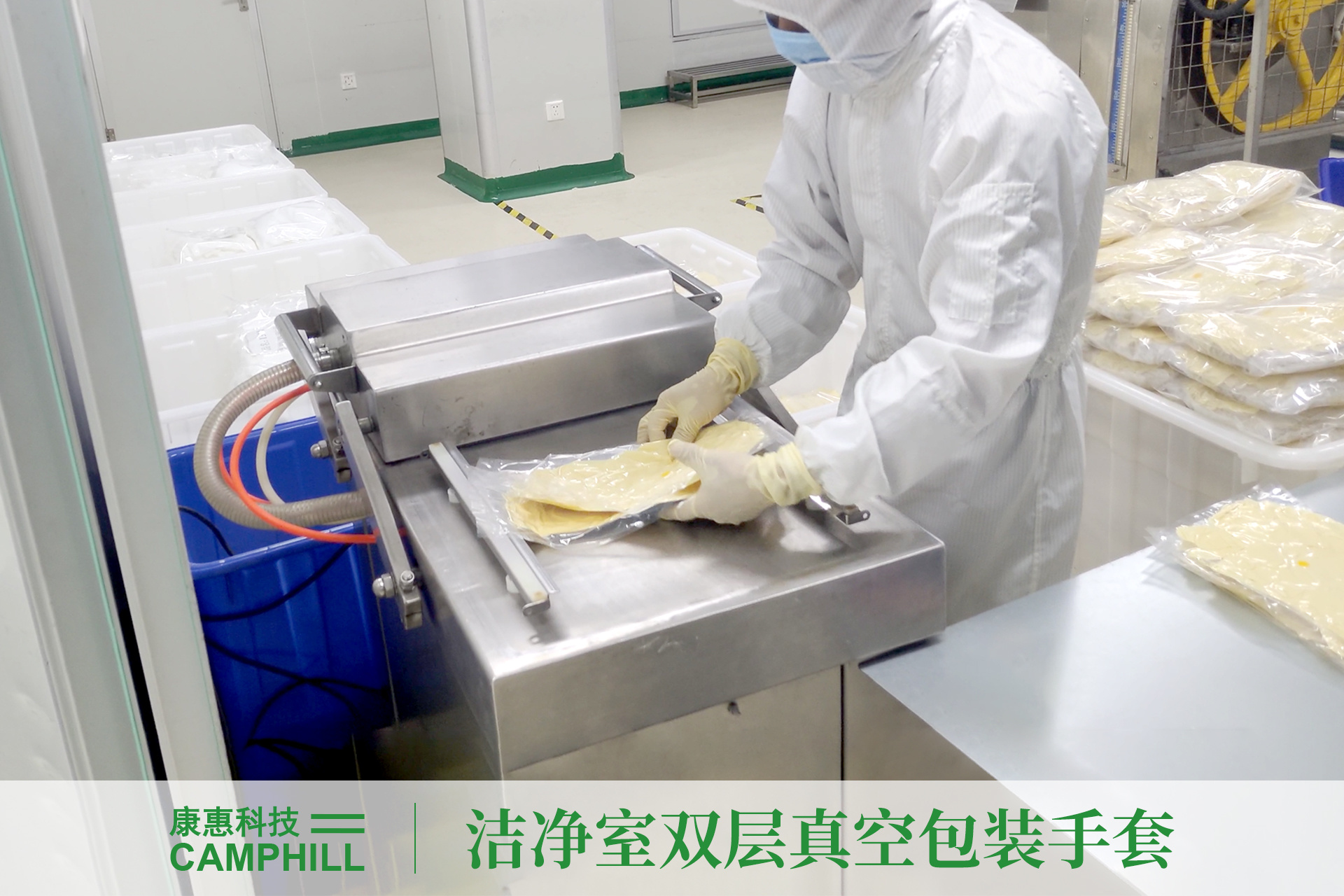

Cleanroom double vacuum packaging

1. Improve cleanlinessThe outer layer of vacuum packaging for gloves can effectively prevent contamination during transportation and storage. When entering the cleanroom, the outer layer of vacuum packaging is removed,ensuring the cleanliness of the gloves upon entering the cleanroom.

Compared to ordinary packaged gloves, double vacuum packaged gloves significantly reduce particulate and microbial contamination,

which helps improve the production environment of the cleanroom.

2. Improve product qualityThe inner layer of vacuum packaging for gloves effectively isolates external air,preventing contamination from microorganisms, dust, etc., during transportation and storage.Additionally, double vacuum packaging makes gloves less prone to damage during transportation, reducing the risk of product contamination. Furthermore, double vacuum packaging can also

reduce the oxidation rate of the gloves,

which is beneficial for improving product quality.Kanghui Technology's own laboratory1. Physical and chemical laboratoryTests the physical and chemical properties of products, such as testing the gloves forpinholes,

physical dimensions (length, width, thickness),

tear strength and elongation at break (before and after aging),

appearance (impurities, dirt, black spots, color difference, poor edge rolling, damage, holes, etc.),stretching performance (elongation and tear strength before and after aging), as well as the gloves'water permeability.And through the LPC detector,tests the gloves forliquid particle countto see if it meets standards.2. Microbiology laboratoryMainly conductssterility testing,such as colony testing that meets the standards of the pharmaceutical, food, and other industries. Apositive control roomis set up to provide a fixed space for testing contaminated samples.Through thebacterial filtration efficiency tester.液态尘粒数量是否符合标准。

2.微生物实验室

主要进行无菌检查,比如符合制药、食品等行业标准的菌落检测。并设置了阳性对照间,提供一个固定的空间操作有菌的检测。

通过细菌过滤效率测试仪Under certain environmental conditions, test the filtration efficiency of filtering materials such as gloves, masks, or protective clothing for bacterial particles; throughgas chromatography,detect the residual amount of ethylene oxide in gloves during the ethylene oxide EO sterilization process; and haveparticle filtration efficiency testing instrument, used for testing the protective effect and filtration efficiency of daily protective masks and respirators against particulate matter.

3. Anti-static laboratory

used for conductinganti-static testing, targeting ESD static protection products for anti-static performance evaluation, such as testing gloves'point-to-point resistanceandfriction voltage.

Conclusion

Cleanroom gloves are an important equipment to ensure product quality and employee health, and their role cannot be ignored. Understanding the technical performance of cleanroom gloves, purchasing and using them properly will lay a solid foundation for the development of the cleanroom industry in our country. Let us work together to protect the "hands" of fine craftsmanship and contribute to the construction of a strong technological nation.

10

2025-11

19

2025-05

11

2025-04

22

2025-01

BIOCHINA 2025 (10th) YiMao Biotechnology Industry Exhibition

17

2025-01

2025 Camphill Technology & SUZUKI Product Sharing Conference

09

2025-01

China Medical Equipment Fair Spring Shanghai CMEF

Hello, what can we do for you?

* Note: Please be sure to fill in the information standard and keep the communication unblocked. We will get in touch with you as soon as possible.