09

2025

-

01

Anti-static cleanroom suit | The silent guardian indispensable to the technology industry

Author:

With the rapid development of technology, the issue of static electricity, which is unfamiliar yet present around us, has gradually come into our view. In fields such as electronic manufacturing, biotechnology, and precision instruments,the generation of static electricity can not only damage products but also pose hazards to workers.Anti-static cleanroom clothing worn on the body can suppress the accumulation of charges generated during activities, thereby reducing and weakening static electricity release, becominga powerful tool for controlling static electricity hazards.,又能and can prevent dust from the human body and dust particles released from clothing from damaging the cleanroom environment.It has become an indispensable equipment in these fields.

The generation and hazards of static electricity.

Static electricity is caused by thecontact, separation, and frictionprocesses between objects, leading to the transfer of electrons on the surface or inside of objects, causing them to become charged. In daily life, static electricity phenomena are everywhere, such asstatic electricity generated by friction of clothes, static electricity generated by contact between the human body and object surfaces.等。

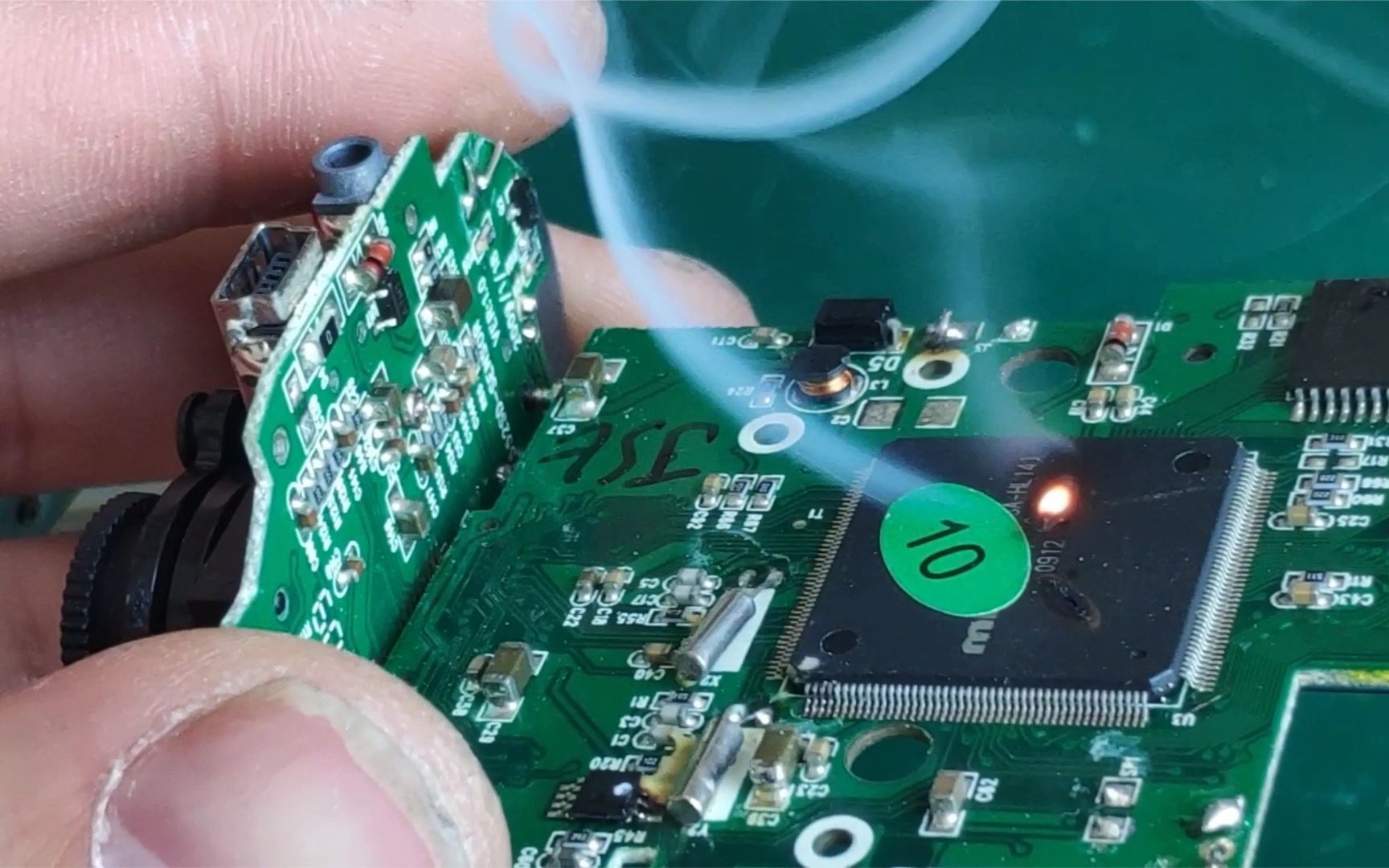

Static electricity candamage electronic components, causing failure or reducing product lifespan,and if anti-static measures are not taken,it willgreatly reduce the yield.Therefore, in static-sensitive industries, anti-static measures are crucial.

What is anti-static cleanroom clothing?

Anti-static clothingcan be made fromordinary pure cotton fabric,which can meet our strict anti-static standards, but it isprone to releasing particulate matter.Therefore, such clothingis not suitable for entering cleanrooms.However, they are an ideal choice inmanufacturing sites such as pharmaceutical factories and television factories.则是理想之选。

Relatively speaking,cleanroom clothingmust be made from long fiber materials such aspolyester or nylon.It cannot useordinary pure cotton fabric. Fabrics woven from long fiber synthetic materials like polyester and nylon,have higher resistance and voltage generated by friction compared to cotton fabrics.其电阻和摩擦产生的电压较高于棉质面料If not treated for anti-static, they cangenerate thousands and tens of thousands of volts,which poses a serious threat to electronic products.

Therefore,Anti-static clothingthe fabric should be made fromlow-resistancefibers,such as pure cotton threads;;cleanroom clothingthe fabric should be made fromlong fiberthreads, such as polyester!Anti-static cleanroom clothing is made from long fiber threads that require special treatment!

To create protective clothing that is both

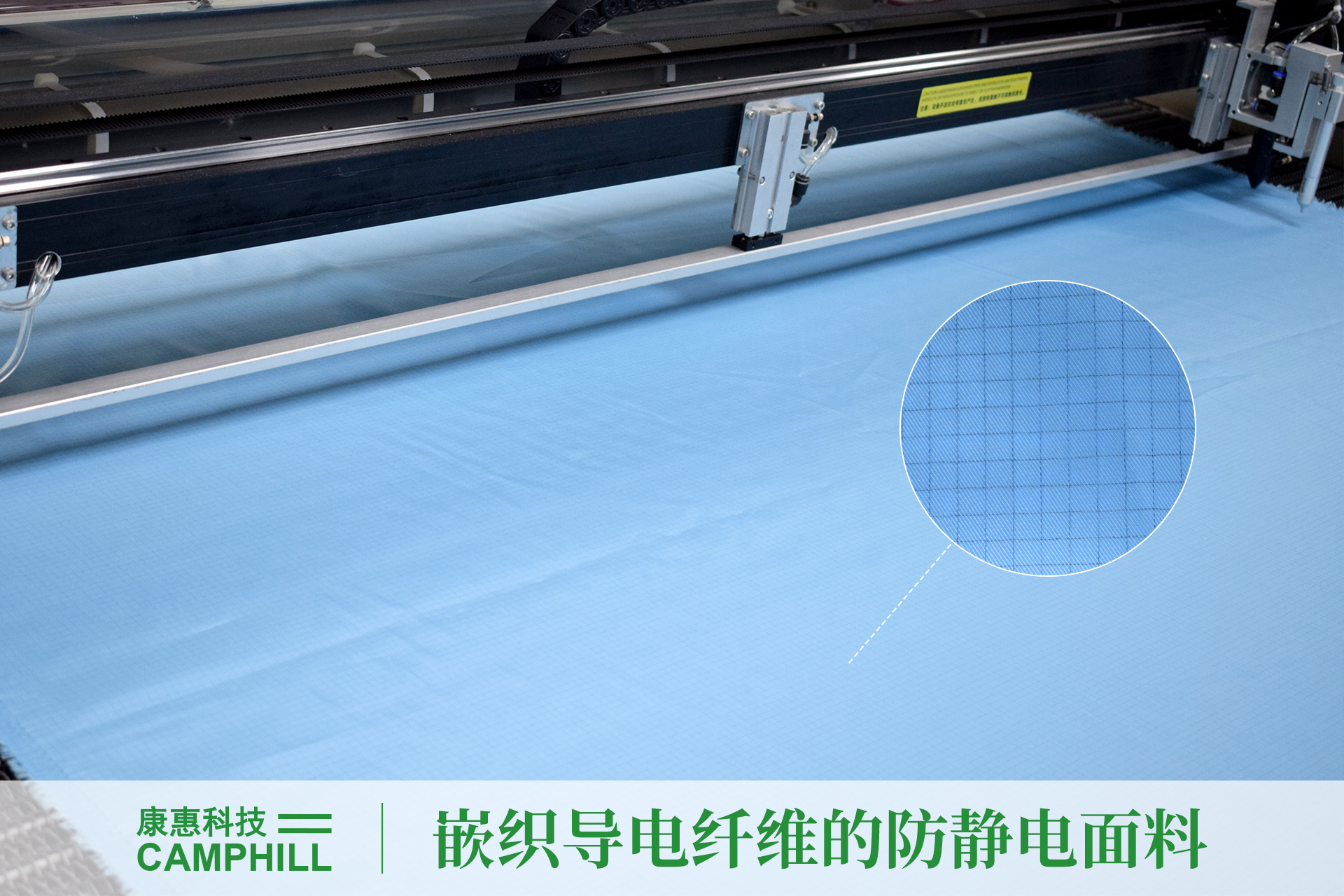

anti-static and dust-free, maintaining a clean environment, long fiber polyester is the preferred material.However, due to the tendency of polyester fabric to generate static electricity and attract dust particles, it is necessary toadd conductive fibers for anti-static treatment.For example,

"Kanghui Technology"anti-static cleanroom clothing,useshigh-quality long fiber polyester fibersandfully conductive carbon fibers, woven or knittedfabrics, throughspecial cutting such as laserand then sewn together! Such clothing not only prevents static electricity but also dissipates it, reducing surface friction voltage, while long fibers effectively prevent the release of particulates.Applications of anti-static cleanroom clothing.

Anti-static cleanroom clothing is mainly used in the following industries:

1. Electronics, semiconductors, precision manufacturing, optical and optoelectronic industries:

to protect sensitive components from static damage.2. Laboratories:

to prevent static interference with experimental results.3. Food industry:

to effectively prevent dust, bacteria, and other contaminants from polluting food, ensuring food safety, and improving food packaging quality to prevent static from attracting dust.4. Biotechnology and pharmaceutical industries:

to improve the cleanliness of the production environment, reduce product contamination risks, and ensure the quality of medicines.The conductive principle of anti-static cleanroom clothing.

1. Methods of anti-static processing for fabrics:

1.面料的防静电加工方法:

① Fabric useAntistatic agentProcessing;

② Aiming to improve the moisture absorption of the fabricFiber graft modification, hydrophilic fiberblending and interweaving;

③ Blending orEmbedding conductive fibersgreatly reduce the yield.

2. Comparison of three methods

The first two types of methodswork by increasing the moisture regain of the fabric, reducing insulation, and accelerating static electricity leakage. Therefore, if in a dry environment or after multiple washes, the processing effect may be either not durable or not significant, usually applied to ordinary clothing fabrics. However,the third method can effectively and durably solve the static electricity problem of textiles, and is currently widely used in the production of antistatic cleanroom clothing. However, many businesses on the market use the first two methods to produce antistatic cleanroom clothing to save costs, which are not durable and have weak antistatic performance, and may even easily lose their antistatic effect, soit is recommended that everyone be vigilant and choose carefully.greatly reduce the yield.

The antistatic performance of antistatic cleanroom clothing ensures that static electricity does not harm the human body or damage components,when grounded.The static electricity on the fabric will be neutralized by the corona discharge of the conductive fibers, and will alsobe discharged to the ground through the conductive fibers.When not grounded, it mainly relies on the weak corona discharge of the conductive fibersto dissipate electricity. To achieve this, the antistatic cleanroom clothing itself must meet certain standards, such as,the friction voltage needs to be less than 500V.Surface resistance;needs to be in~10106Ω9, this range can better discharge and dissipate static electricity.之间,这个范围能更好的泄放和耗散静电。

How to choose antistatic cleanroom clothing?

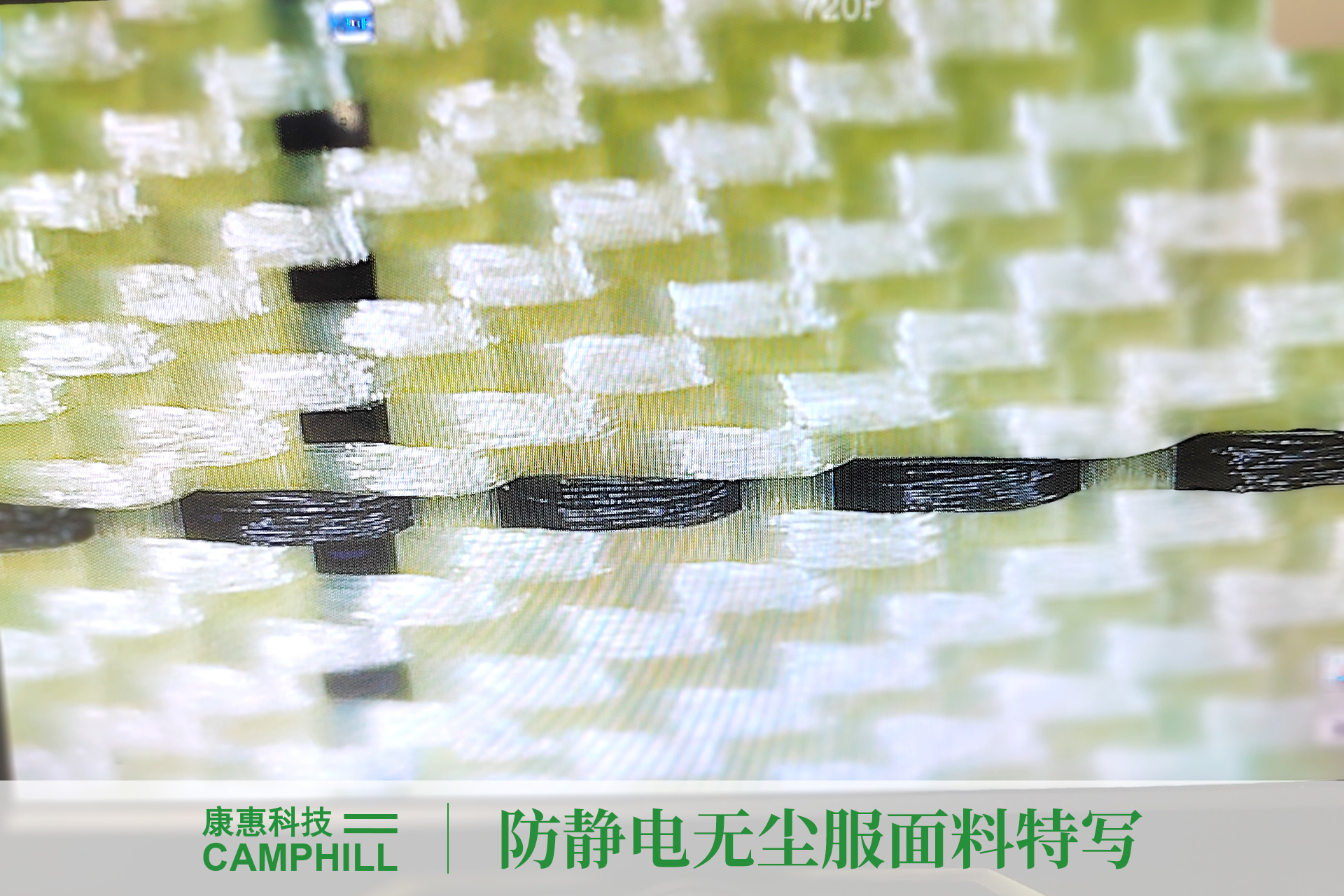

Antistatic cleanroom clothing is made ofpolyester filament fabric containing fully conductive carbon fibers.It has excellent and durable static dust prevention function, effectively releasing static charges from the human body for a long time.Using high-density edge sewing, low dust emission, meeting the needs of different cleanrooms.The product can be washed repeatedlyand undergo multiplehigh-pressure moist heat sterilization.greatly reduce the yield.

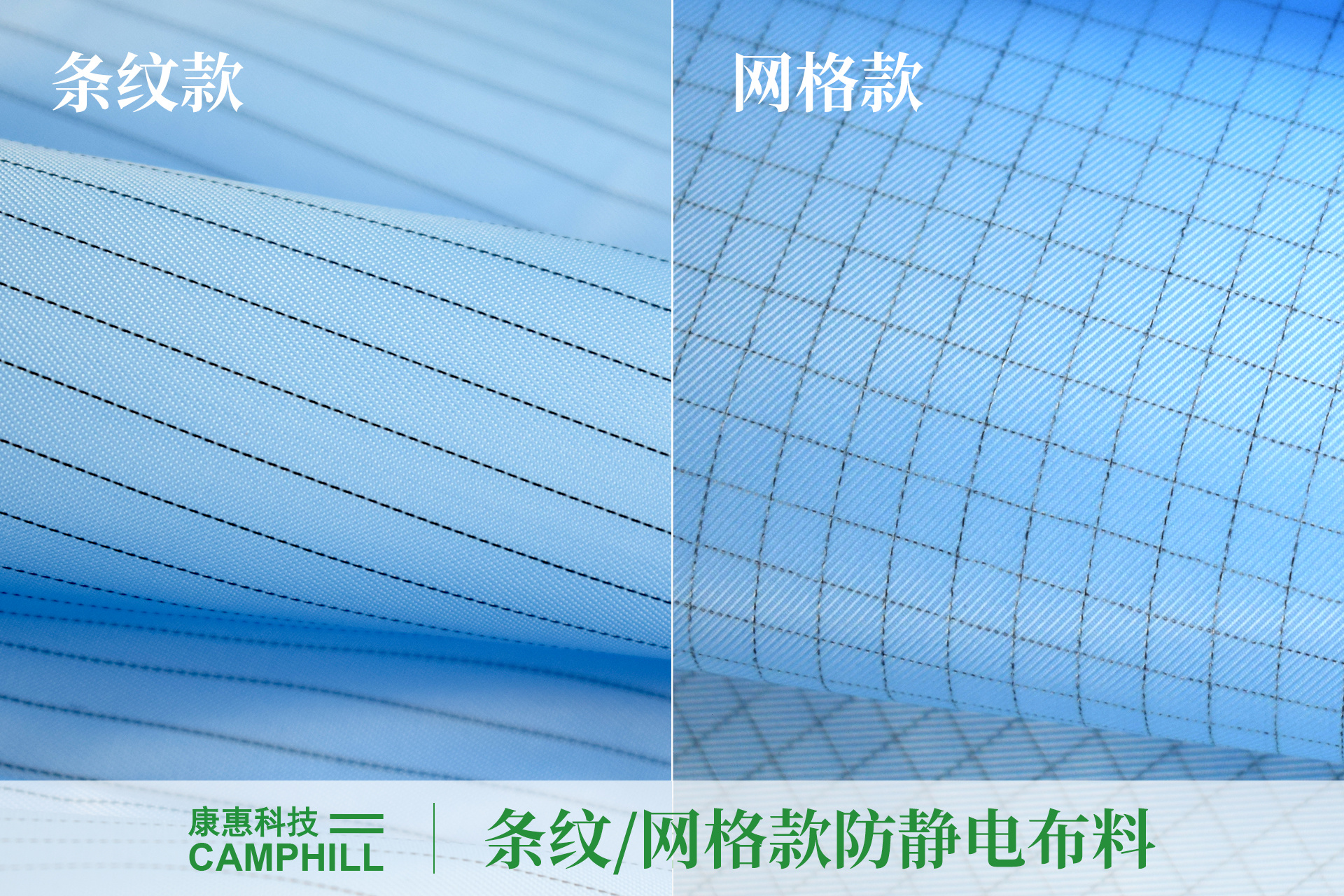

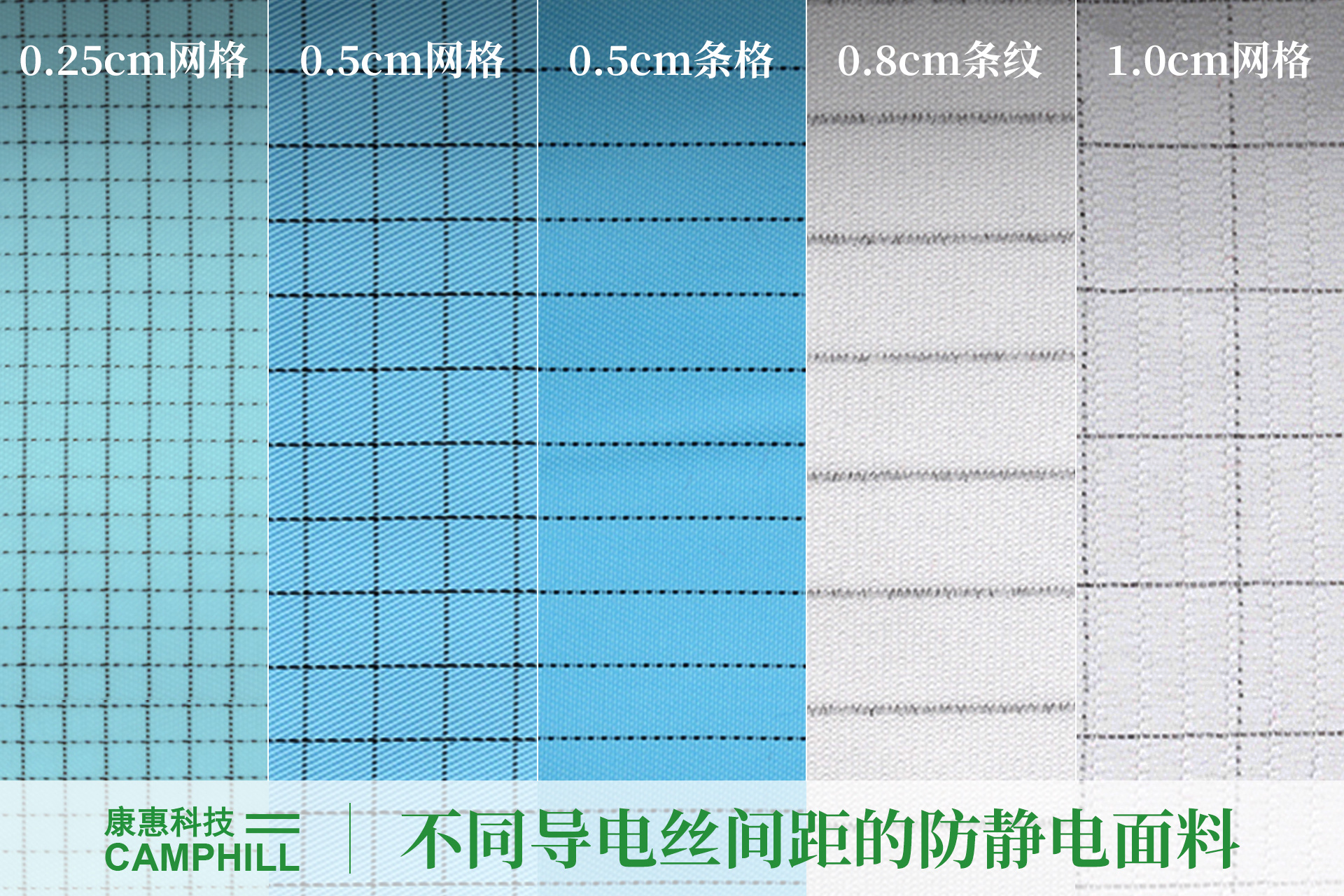

1. Stripes/Grids

● The striped antistatic cleanroom clothing fabric only has conductive threads embedded in thewarp direction.;

● The grid antistatic cleanroom clothing fabric has conductive threads embedded in both thewarp and weft directions during weaving,forming agrid pattern.greatly reduce the yield.

2. Conductive thread spacing

Depending on the spacing of the conductive threads, it is divided into specifications such as 0.25cm grid, 0.5cm stripe/grid, 0.8cm stripe, 1cm grid, etc.,the denser the conductive fibers, the better the antistatic performance.The performance of grid antistatic cleanroom clothing fabric is more stable and durable, and the price is also higher.Generally speaking, antistatic fabric with a conductive thread spacing of 0.5cm can meet general antistatic needs.

3. Fabric density

The density of antistatic cleanroom clothing fabric refers to the number ofwarp and weft yarns arranged per square inch.It is also called warp and weft density, usually expressed as "number of warp yarns × number of weft yarns," but can also be represented by D. Thegreater the density of the antistatic cleanroom clothing fabric,the thicker the fabric of the antistatic work clothing,the less permeable it is.,The smaller the density,the thicker the fabric of the antistatic work clothing,the thinner and more permeable it is.Common specifications for antistatic work clothing fabric include 75D and 100D.

75D fabric has fine yarns,good breathability, relatively soft fabric, and high wearing comfort, but poor abrasion resistance;100D fabric has thicker yarns,better abrasion resistance, but is relatively stiff, with slightly lower wearing comfort and slightly poorer breathability.

Under the same conditions,the antistatic performance of 75D fabric is slightly better than that of 100D fabric.This is because the finer the fiber, the more evenly the conductive fibers are distributed, resulting in better antistatic performance.

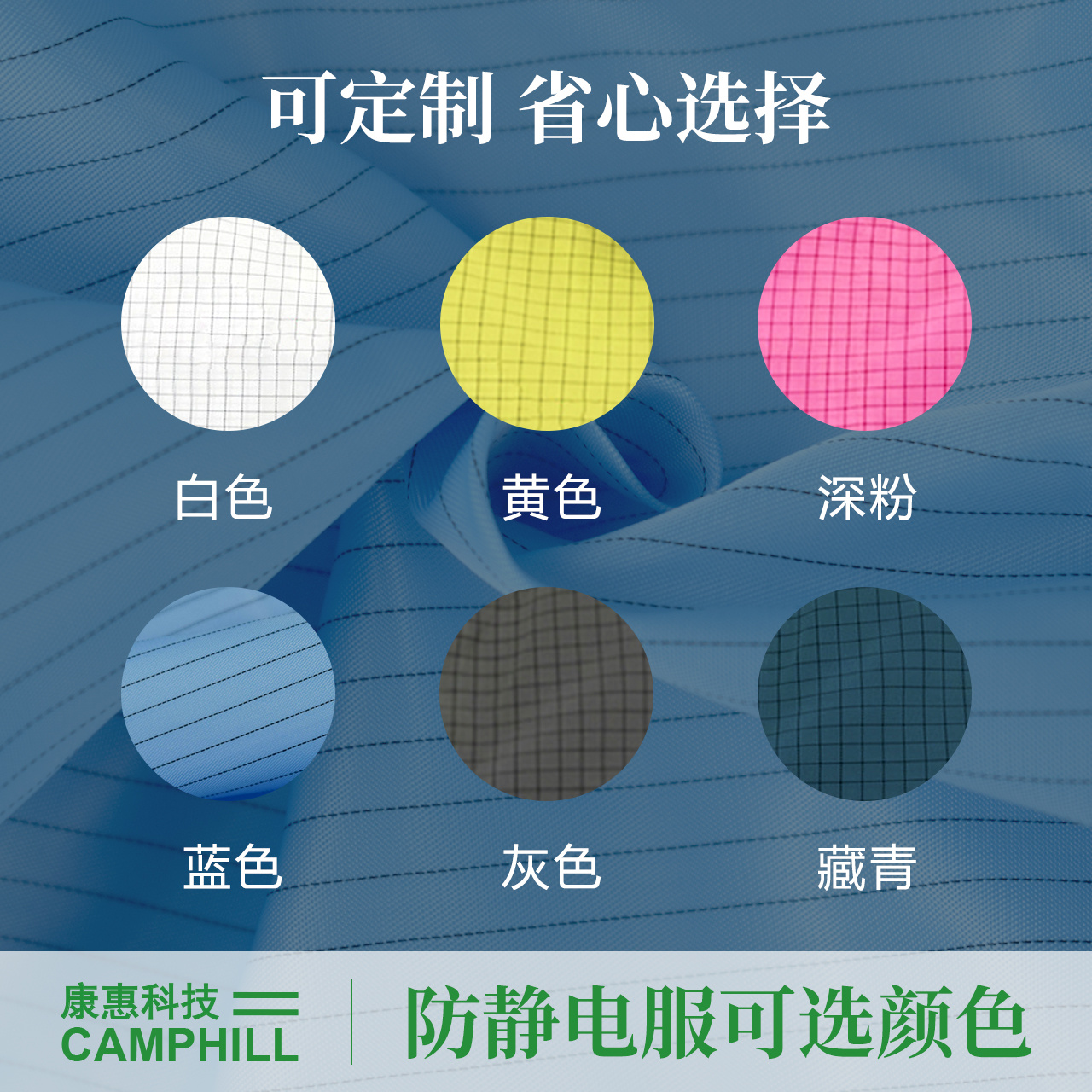

4. Color selection

Antistatic fabricis available in various colors.The commonly used colors are white, blue, deep pink, yellow, gray, and navy blue. If there are different requirements, you can contact the manufacturer for customization.

Styles of anti-static cleanroom clothing

1. Lab coat:YesThe requirements for anti-static cleanroom clothing are not high.For industries with high anti-static requirements, such as precision electronics, it is not recommended to use anti-static lab coats.

2. Split suit (top + pants):Convenient to wear, but compared to one-piece anti-static cleanroom clothing, its overall anti-static performance still has a certain gap,generally used in production workshops above class 10,000.It is not recommended for workshops with higher cleanliness levels, such as class 100 or class 1,000.

3. Split four-piece suit (hooded top + pants):Pairing with gloves, masks, etc., provides comprehensive protection for the body, preventing static electricity from being generated from head to toe,with a higher cleanliness level.

4. Hooded split suit (hooded top + pants):Pairing with anti-static shoes, gloves, masks, etc., provides protection from head to toe,with a higher cleanliness level.

5. Three-piece suit (pants connected to top and hood):Pairing with anti-static shoes, gloves, masks, etc., forms a complete closed system to prevent micro-dust from entering and avoid static electricity generation,with a higher cleanliness level.greatly reduce the yield.

6. Special styles:Customized according to specific industry needs, such as10-class cleanroom anti-static cleanroom clothing.等。

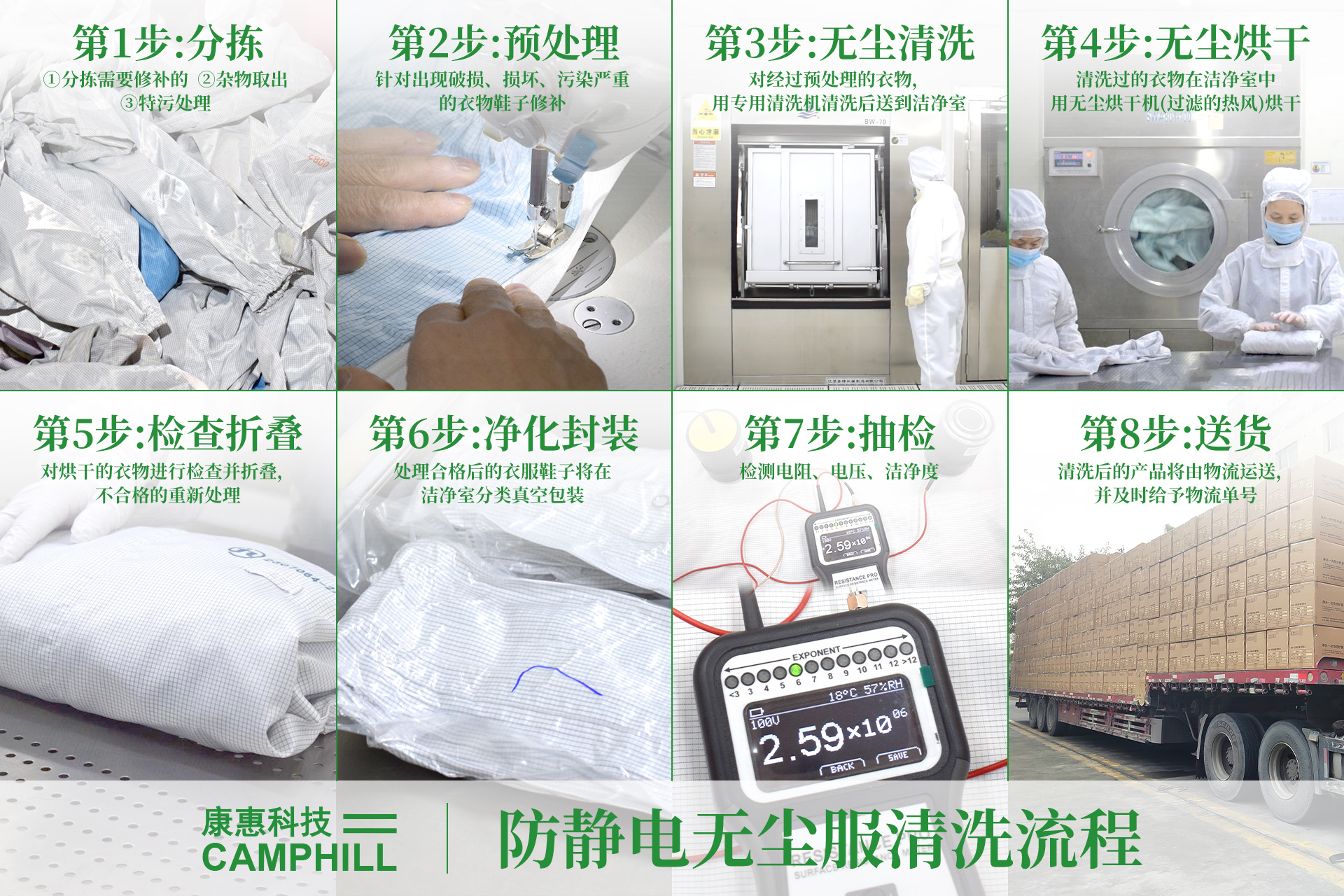

Cleaning of anti-static cleanroom clothing

1. Recommendations

It is recommended thata professional service teamanti-static cleanroom clothing,clean your anti-static cleanroom clothing. If you do not have this condition, we suggest:

①Washing with room temperature water, machine washable,with a water temperature recommended tonot exceed 60℃,to avoid high temperatures damaging conductive fibers;

② It is recommended to use neutral detergents,with a pH value of 6~8,to avoid strong acid or strong alkaline detergents;

③ During the washing process,sharp objects should be avoidedto prevent scratching and wear on the clothing;

④ Can be air-dried or tumble-dried,when tumble-drying, it is recommended that the temperature does not exceed 60℃.greatly reduce the yield.

2. Washing frequency of anti-static cleanroom clothing

Based on daily use and washing wear, it is recommended to wash anti-static cleanroom clothingafter 50 washes (≥16.5 hours)for replacement.

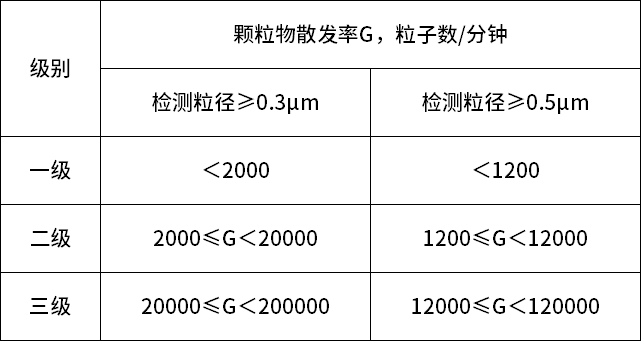

3. Cleanliness performance

The dust generation rate is according toIEST-RP-CC003.3 Hamker rolling test method,and must meet the following standards:

anti-static cleanroom clothing,There is a cleaning service, and after cleaning, it can meet the IEST-RP-CC003.3 requirements.

Testing of anti-static cleanroom clothing's anti-static performance

1. Resistance value testing

The main function of anti-static cleanroom clothing is to prevent static electricity hazards, so its resistance value is a very important indicator. According to relevant standards,the resistance value of anti-static cleanroom clothing should be controlled between 106Ω9Ω.Exceeding this range indicates a problem with anti-static performance.

2. Pressure resistance testing

During use, anti-static cleanroom clothing may be subjected to various mechanical pressures, so its pressure resistance is also an important testing indicator. Generally,the testing personnel will apply pressure to the anti-static cleanroom clothing to test the garment's stretchability and pressure resistance.The standard requires that the clothing should be able to withstand a certain amount of tensile force without damage.

3. Durability of anti-static performance testing

The durability of anti-static cleanroom clothing refers to its ability to continuously maintain anti-static performance during use, preventing static electricity hazards. For this, anti-static cleanroom clothing also needs to undergo corresponding testing.Generally, testing personnel will check the wear resistance and anti-static durability of the anti-static cleanroom clothing through continuous rolling and friction.The standard requires that anti-static cleanroom clothing should maintain a resistance value of 106Ω9Ω after undergoing a certain amount of wear.

anti-static cleanroom clothing,Own anti-static laboratory for conductinganti-static testing,evaluating the anti-static performance of ESD protective products, such as testing the anti-static cleanroom clothing'spoint-to-point resistance,, andneeds to be infriction voltage, etc.Storage and maintenance of anti-static cleanroom clothing.greatly reduce the yield.

防静电无尘服的存储保养

1. The storage environment should be dry and well-ventilated, avoiding humidity and high temperatures.

2. Avoid contact with sharp objects to prevent damage to the fabric.

3. Regularly check the conductive performance of the anti-static cleanroom suit to ensure its protective effect.

Precautions for wearing anti-static cleanroom suits

When wearing anti-static cleanroom suits, the following precautions should be observed:

1. According todifferent locationsand the different electrostatic sensitivity of the processed objects, selectanti-static cleanroom suits of different levels.greatly reduce the yield.

2.Prohibitedto attach or wearanymetal objects3. Thegreatly reduce the yield.

putting on and taking off of the anti-static cleanroom suitshould be done inthe designated changing room.It is not allowed to wear or take off the anti-static cleanroom suit at the site of operation of electrostatic sensitive products.4. Before wearing the anti-static cleanroom suit, it should berandomlyselected for several pieces

to test the charge,and after wearing for a certain period or when the wearer feels an electric shock,retesting should be conducted.5. When wearing the anti-static cleanroom suit,all buttons should be fastened,and it should be kept as far as possible from being in a state close to undressing.greatly reduce the yield.

6. When wearing the anti-static cleanroom suit, it must bepaired with anti-static shoes,as well as corresponding anti-static hoods and gloves, and the ground should also be

anti-static flooring with a grounding system.The outer clothing should completely cover the inner clothing.The split-type top should be long enough to cover the waistband, and it should not expose the waistband when bending.8. The anti-static cleanroom suit mustbe replaced strictly according to the usage cycle,greatly reduce the yield.

7.to avoid its anti-static function being weakened after multiple washes and failing to meet requirements.Does it still have conductive properties after damage?

If the anti-static cleanroom suit is damaged, its conductive performance may be affected. If the damaged area is small,and the conductive fibers are not damaged, it still has certain conductive properties.It is recommended to conduct a conductivity test, and if qualified, it can be used;

if the damage is larger, the conductive performance will significantly decrease, and it should be replaced in a timely manner.

Can it be repaired?For damaged anti-static cleanroom suits,repairs can be made.However, the conductive performance of the repaired clothing may decline,

and it is recommended to repair key areas,

and conduct a conductivity test after repair.ConclusionAs a silent guardian indispensable to the technology industry, anti-static cleanroom suits play an important role in many fields. With the continuous advancement of technology, anti-static cleanroom suits will become more refined, providing strong support for the cleanroom industry in our country.建议在关键部位进行修补,并在修补后进行导电性能测试greatly reduce the yield.

结语

防静电无尘服作为科技产业离不开的无声卫士,在众多领域发挥着重要作用。随着科技的不断进步,防静电无尘服将更加完善,为我国无尘室事业提供有力支持。

10

2025-11

19

2025-05

11

2025-04

22

2025-01

BIOCHINA 2025 (10th) YiMao Biotechnology Industry Exhibition

17

2025-01

2025 Camphill Technology & SUZUKI Product Sharing Conference

09

2025-01

China Medical Equipment Fair Spring Shanghai CMEF

Hello, what can we do for you?

* Note: Please be sure to fill in the information standard and keep the communication unblocked. We will get in touch with you as soon as possible.